Description

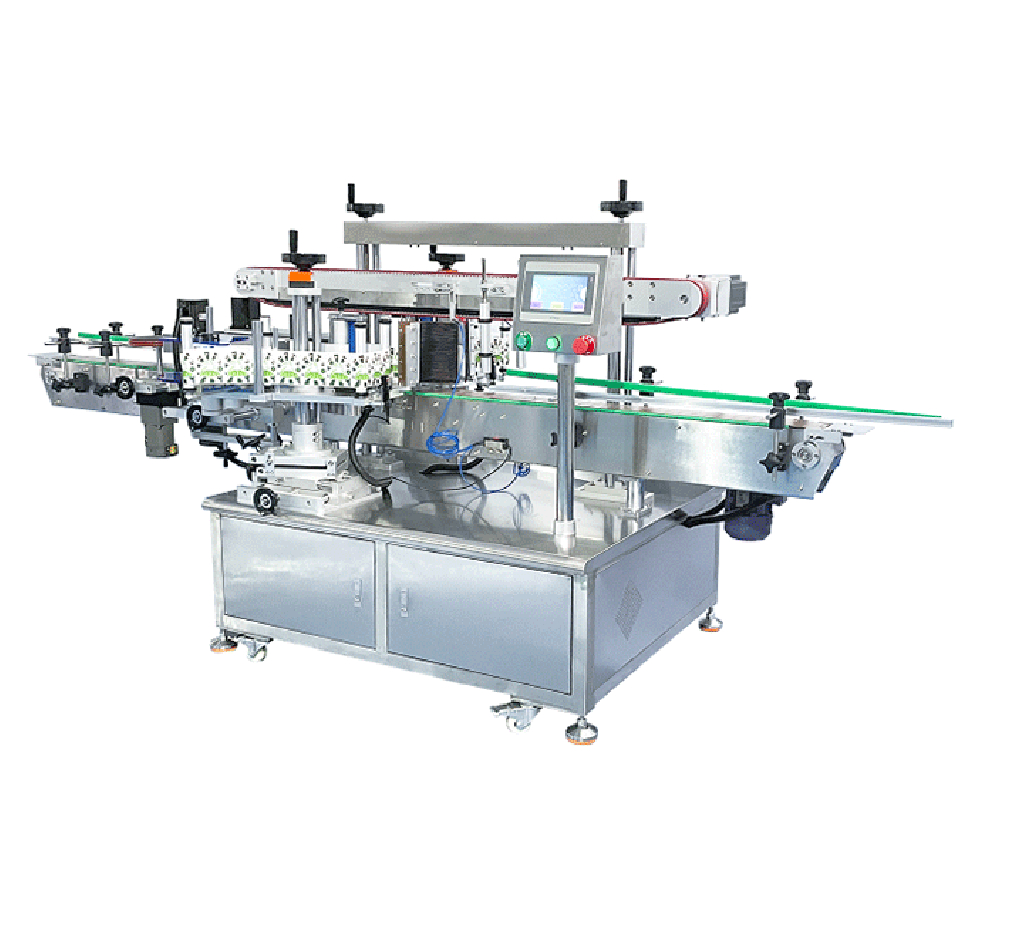

| Labeling accuracy | ±1mm (excluding product and label errors) |

| Labeling speed | 30 ~ 160 pieces/min (depending on product and label size) |

| Applicable product size | Flat bottle: Length: 20mm ~ 250mm |

| Width: 40mm ~ 100mm (round bottle diameter 100mm) | |

| Height: 60mm ~ 280mm | |

| Applicable label size | Length: 20mm ~ 200mm |

| Width (including backing paper width) : 20mm ~ 175mm | |

| Overall size | Approx. 3000mm×1450mm×1600mm (length × width × height) |

| Applicable power supply | 220V/50HZ |

| Machine weight | About 300Kg |

Basic function

◆ This machine includes automatic conveyor belt, can be used alone. It can connect filling machine, capping machine and sealing machine to realize automatic production line

◆ Can be affixed to both sides of the bottle double labels, (close one of the labeling head, can be affixed to the single side of the bottle);

◆ Including bottle splitting device, the bottle open a certain distance; Directional device is included to ensure that the bottle is centered in the conveying process; With pressure top belt device, to ensure that the bottle is pressed during the conveying process will not go astray, up and down synchronization.

◆ Including 8 dimension adjustment seat, label head can be up and down, left and right, front and back, tilt adjustable, very convenient

◆ Including positioning round bottle labeling mechanism, stick flat bottle on both sides at the same time can stick round bottle circumference one, two labels

◆ Used in all kinds of square flat bottles such as: lubricating oil, car cleaner, glass water, mineral water, mineral water, beverage bottles, laundry liquid bottles, oil smoke net, honey, chemical reagent bottles, shampoo, health wine, nut bottles, cookie bottles, chili oil bottles, chili sauce bottles and other single-sided or double-sided labeling, while containing round bottles.

Optional function

◆ It can lengthen the conveying and increase the labeling head, and meet the labeling function on the top of the bottle;

◆ Optional transparent label detection eye, suitable for transparent labels;

◆ Optional ribbon coding machine or thermal transfer coding machine, to print the production date on the label and other functions, coding and labeling synchronous, saving processes;

◆ Optional inkjet printer or laser inkjet printer, to achieve the production date and other functions in the product, inkjet labeling synchronous, saving processes