Description

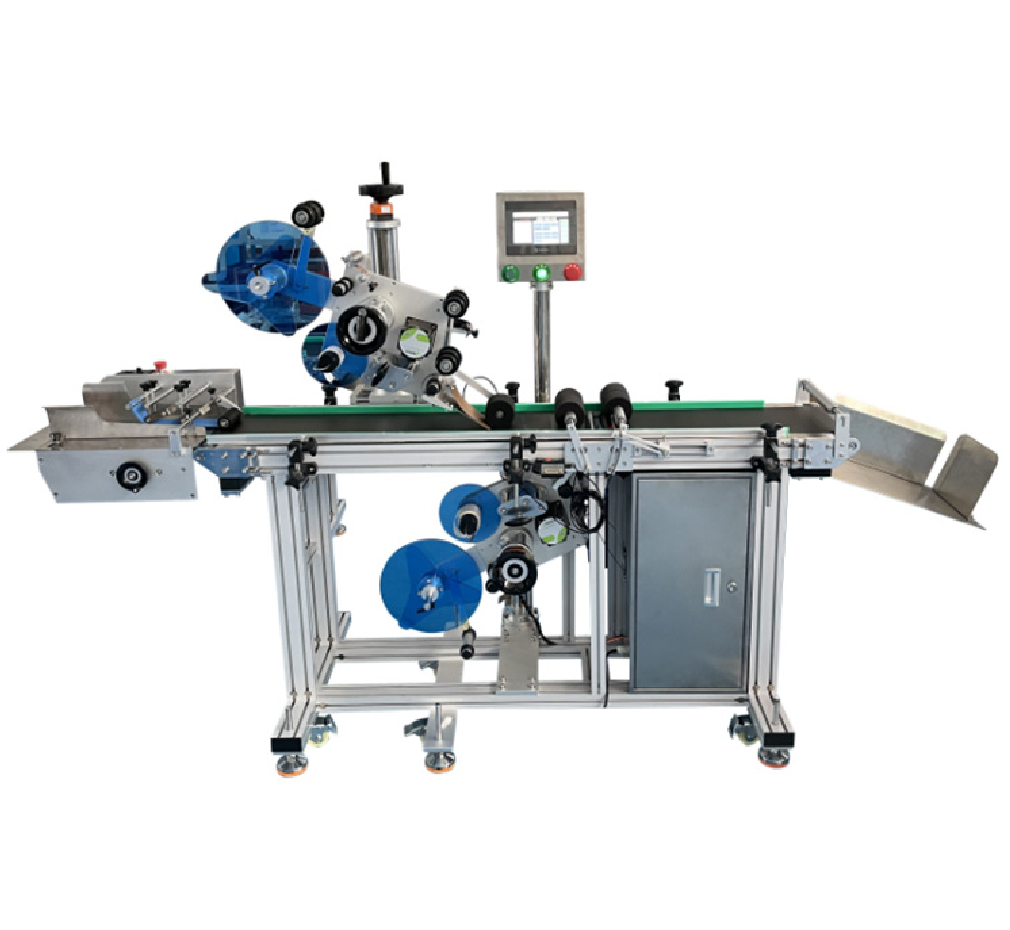

Automatic horizontal round bottle labeling machine

Model: ZK-T402

| Labeling accuracy | ±1mm (excluding product and label errors) |

| Labeling speed | 60 ~ 200 pieces/min (depending on product and label size) |

| Applicable product diameter: (for round bottles) | Outer diameter φ16mm ~ 21mm(Note: compatible with standard configuration) |

| Other specifications are confirmed separately (10 ~ 30mm) or customized in other ranges | |

| Applicable label size | Length: 20mm ~ 100mm |

| Width (base paper width) : 20mm ~ 130mm | |

| Overall size | Approx. 1800mm×7400mm×1400mm (length × width × height) |

| Applicable power supply | 220V/50HZ |

| Machine weight | About 180Kg |

Basic function

◆ This machine includes a drum conveying mechanism, the bottle is placed between the rollers conveying, suitable for all kinds of products standing unstable, horizontal conveying labeling;

◆ This machine includes a feeding mechanism, batch bottles stacked in the feeding box, automatic bottle to the conveyor belt, saving labor;

◆ Using the rolling type labeling method, the bottle is labeled in the process of transportation, and the speed is higher。

◆ The labeling head is equipped with an 8-dimensional adjusting seat, which can adjust the tilt of the labeling head down, left and right by hand wheel, which is very convenient;

◆ Used in small diameter round bottles such as: such as oral liquid bottles, Xylin bottles, test tubes, nucleic acid tubes, lip balm, e-cigarette oil, oil bottles, ham sausage, pens, batteries, etc;

Optional function:

◆ Optional transparent label detection eye, suitable for transparent labels

◆ Optional ribbon coding machine or thermal transfer coding machine, to print the production date on the label and other functions, coding and labeling synchronous, saving processes.

◆ Optional inkjet printer, laser marking machine, to achieve the label, or product production date and other functions, inkjet position can be adjusted.

◆ Optional vibrating plate feeding, or centrifuge feeding, labor saving.