Description

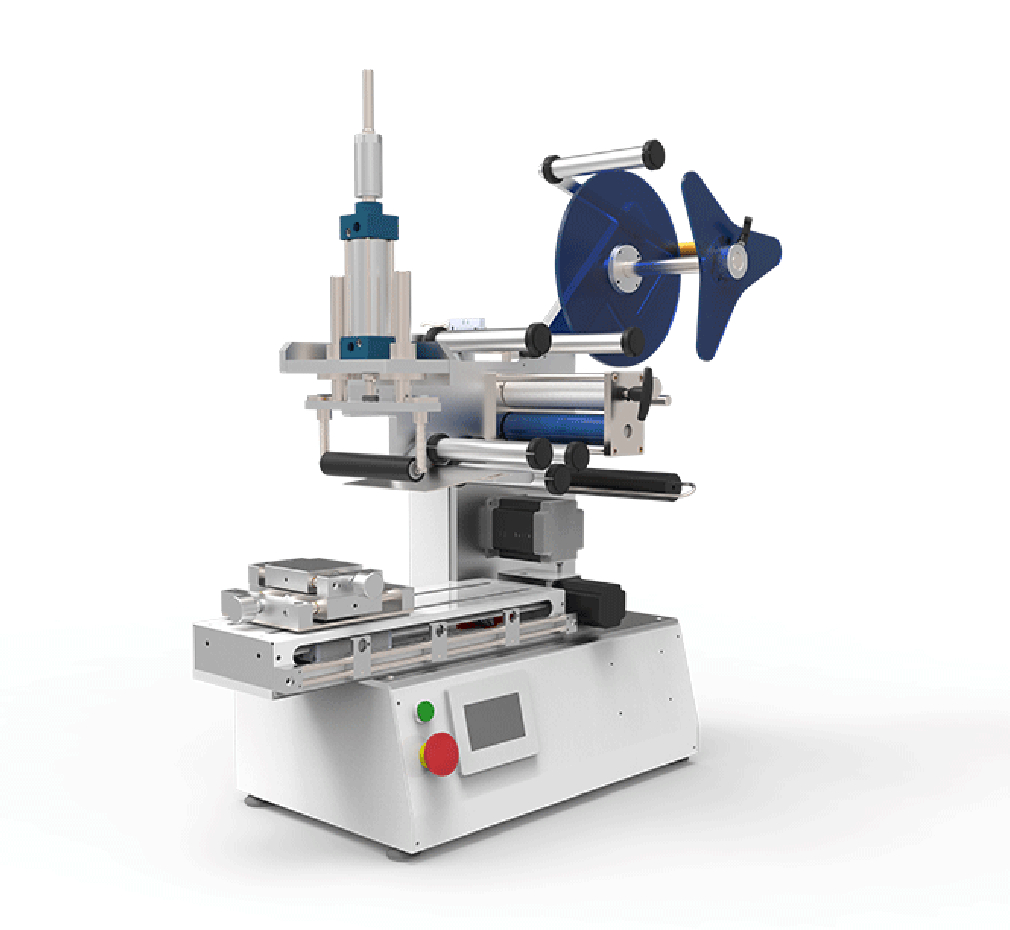

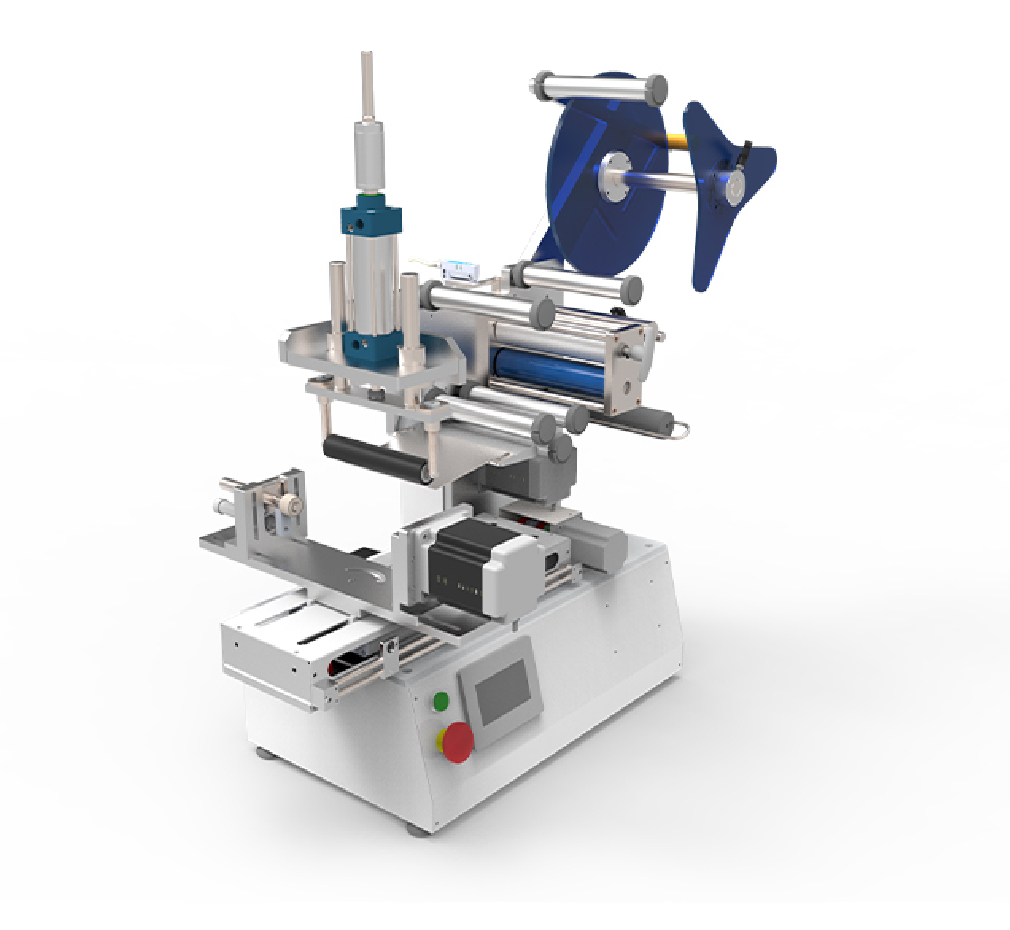

Automatic positioning round bottle labeling machine

Model: ZK-T401

| Labeling accuracy | ±1mm (excluding product and label errors) |

| Labeling speed | 20 ~ 60 pieces/min (depending on product and label size) |

| Applicable product diameter (for round bottles) and height | Diameter: φ40mm ~ φ110mm (other sizes first consult) |

| Height: 25mm ~ 300mm (related to the size and shape ratio of the product) | |

| Applicable label size | Length: 20mm to 285mm |

| Width (base paper width) : 20mm ~ 175mm | |

| Overall size | Approx. 1600mm×1100mm×1400mm (length × width × height) |

| Applicable power supply | 220V/500HZ |

| Machine weight | About 165Kg |

Basic function

◆ This machine includes floor type conveying mechanism, can automatically transport products, can be connected to filling machine, capping machine, sealing machine to achieve automatic production line;

◆ One label can be attached to the round bottle, or two labels;

◆ Cylinder positioning labeling method, stop bottle labeling, effectively eliminate bubbles, high labeling accuracy.

◆ The labeling head is equipped with an 8-dimensional adjusting seat, which can adjust the tilt of the labeling head down, left and right by hand wheel, which is very convenient;

◆ Used in all kinds of round bottles such as: medicine bottles, Xylin bottles, chili sauce bottles, health care products bottles, honey, soy sauce bottles, vinegar bottles, plum bottles, PET bottles, beverage bottles, cosmetics bottles, mineral water bottles, glass bottles, tinplate cans and so on;

Optional function:

◆ Optional transparent label detection eye, suitable for transparent labels

◆ The circular positioning labeling mechanism can be selected to realize the fixed-point labeling function on the bottle with LOGO.

◆ Can be customized to cover the glue shaft, to achieve concave bottle labeling.

◆ Optional ribbon coding machine or thermal transfer coding machine, to print the production date on the label and other functions, coding and labeling synchronous, saving processes;

◆ Optional inkjet printer, laser marking machine, to achieve the label, or product production date and other functions, inkjet position can be adjusted;

◆ Before/after can be matched bottle machine, to achieve automatic bottle, bottle collection, saving labor;

◆ Optional taper labeling special adjusting seat + pressing top, meet a certain taper of the cup and other items labeling;