Description

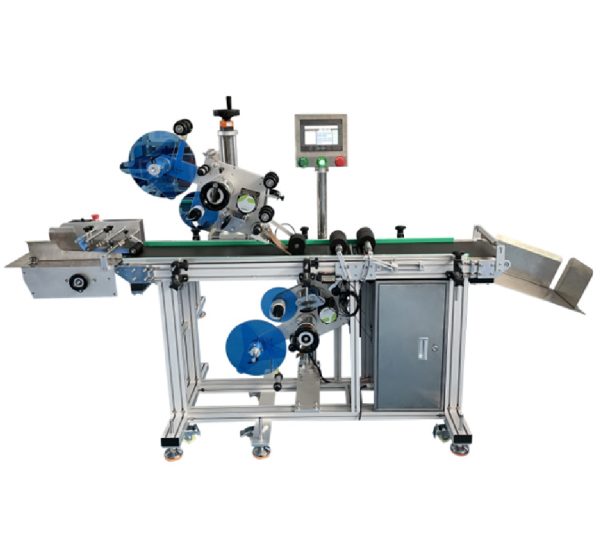

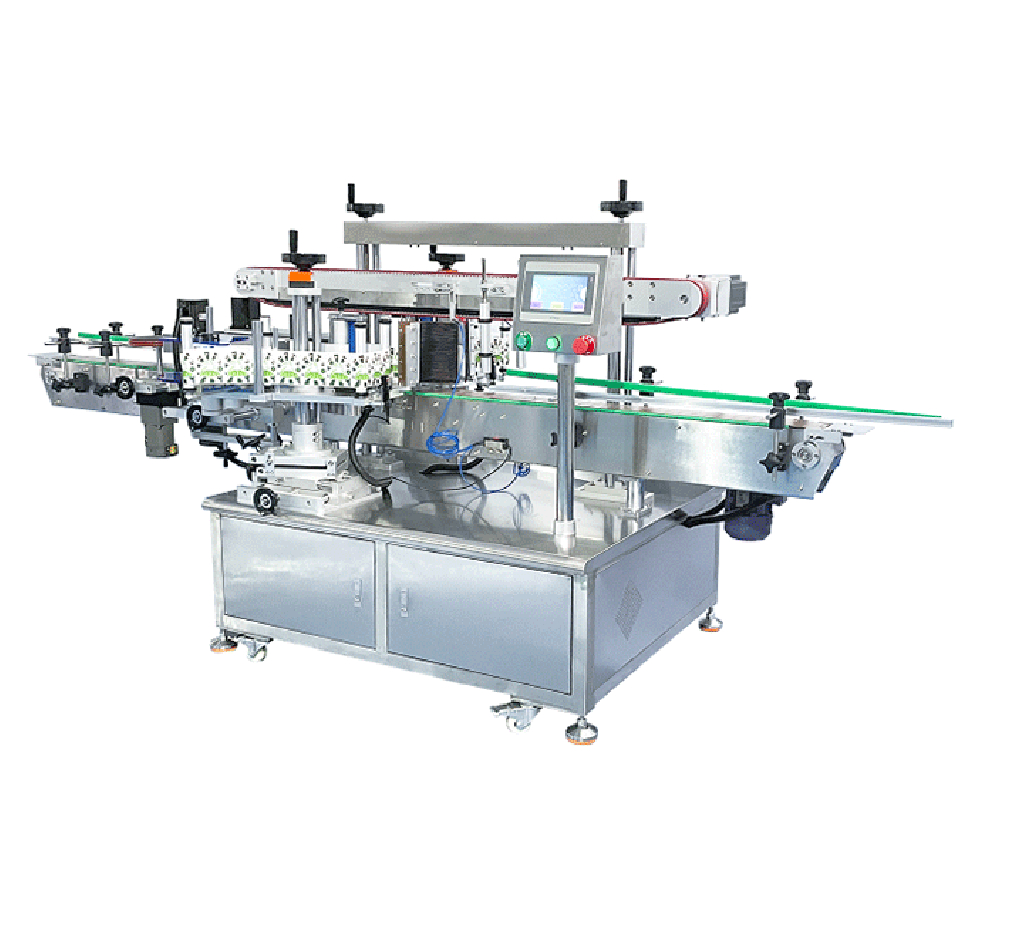

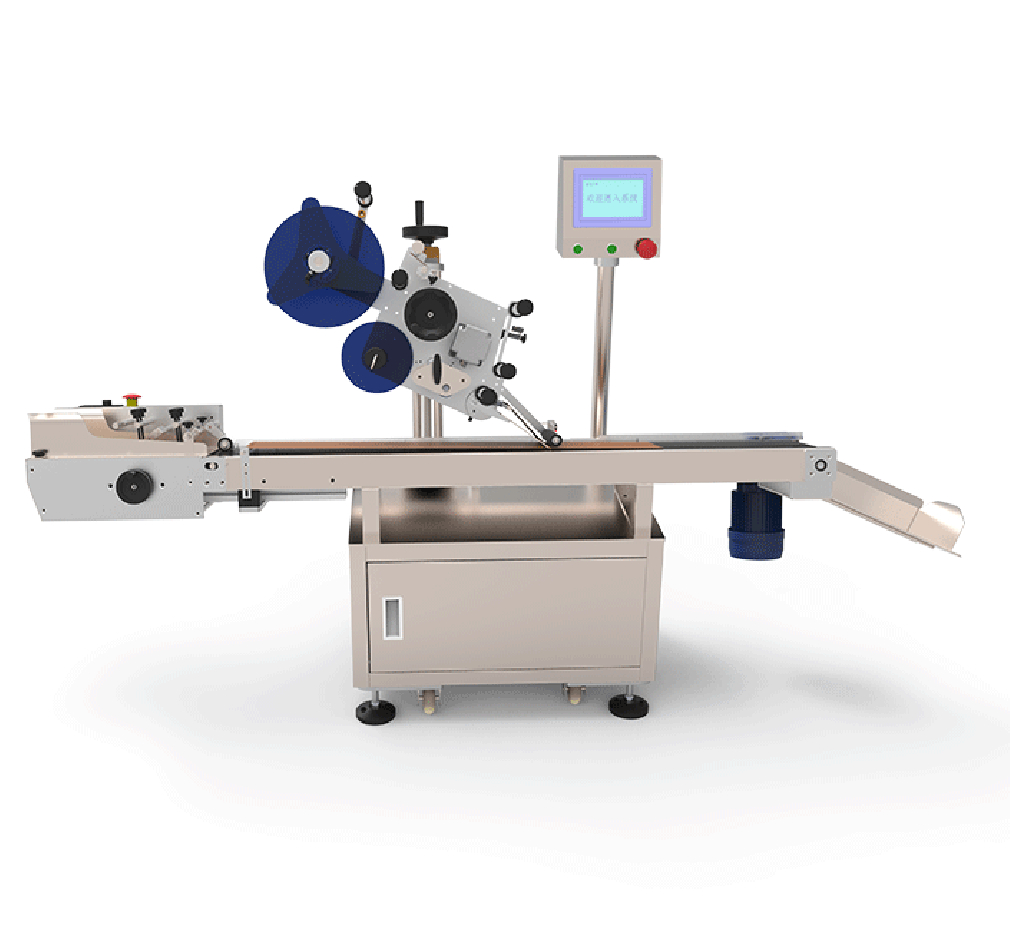

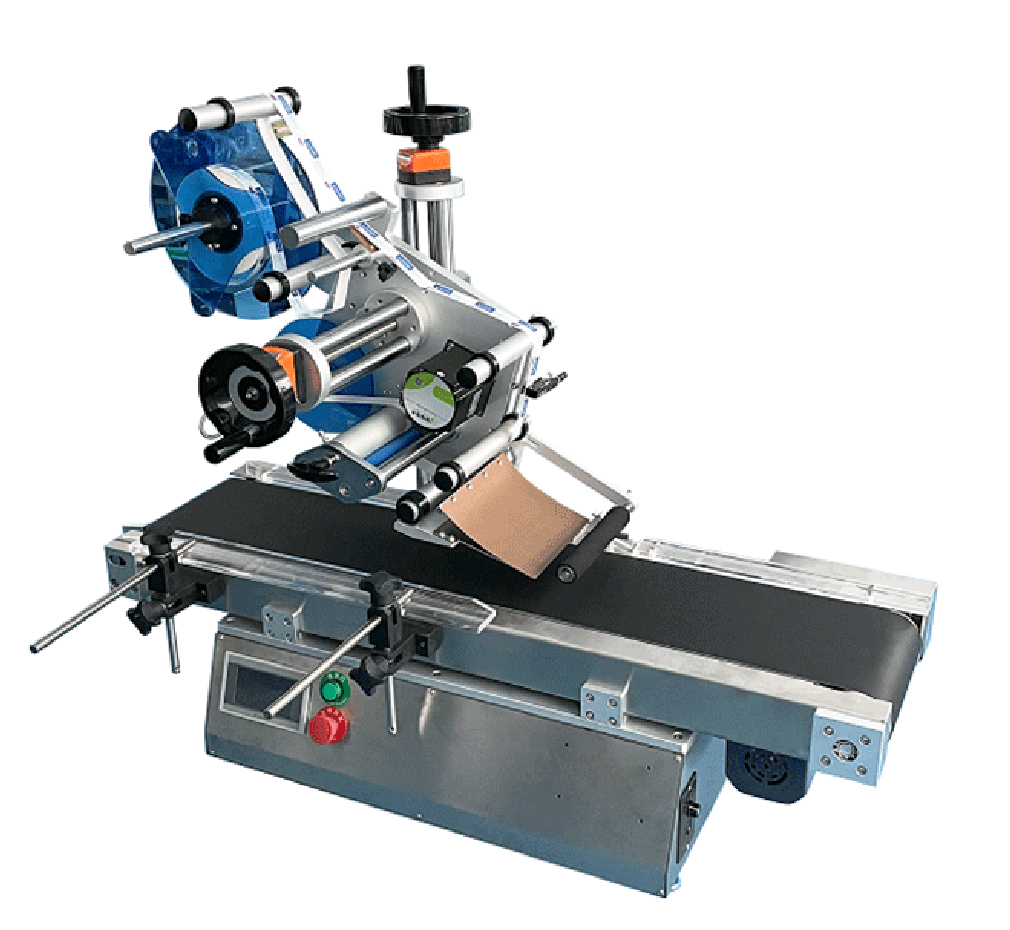

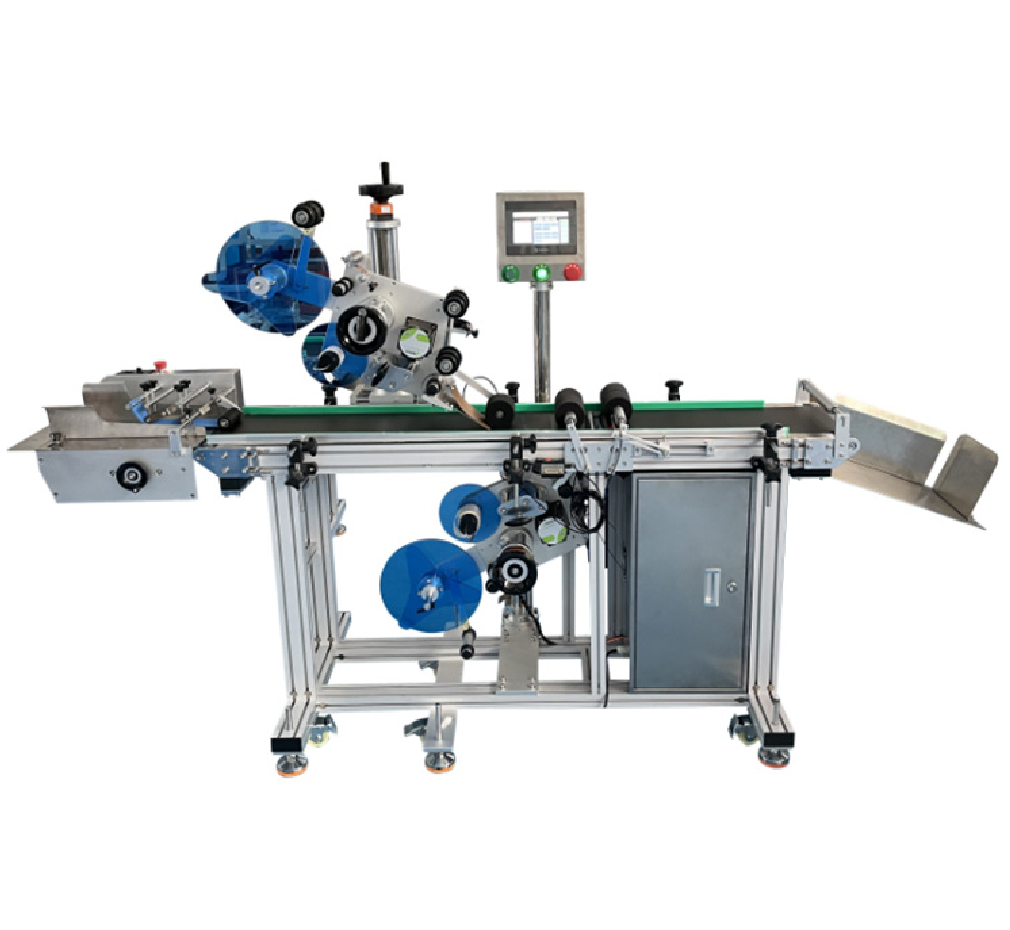

Automatic upper and lower plane double labeling machine

Model: ZK-T304

| Labeling accuracy | ±1mm (excluding product and label errors) |

| Labeling speed | 30 ~ 160 pieces/min (depending on product and label size) |

| Applicable product size | Length: 40mm ~ 250mm(customized) |

| Width: 40mm ~ 200mm(customized) | |

| Height: 0.2mm ~ 100mm(customized) | |

| Applicable label size | Length: 6mm ~ 250mm |

| Width (base paper width) : 20mm ~ 175mm | |

| Overall size | Approx. 2500mm×650mm×1400mm (length × width × height); (including score card, receiving materials) |

| Applicable power supply | 220V/50HZ |

| Machine weight | About 160Kg |

Basic function

◆ The machine includes a floor type conveying mechanism, which can automatically transport products, and can be connected to other lines before and after use;

◆ Including the upper plane labeling head + the lower plane labeling head, and the upper and lower labeling at the same time (the lower header is inserted from the middle of the two sections of transmission to send the label);

◆ Used in a variety of products that need to be labeled on both sides, such as candy boxes, jelly boxes, chocolate boxes, folders, books, paper boxes, electronic products, pet food, etc.

Optional function

◆ Optional transparent label detection eye, suitable for transparent labels;

◆ Optional ribbon coding machine, to print the production date on the label and other functions, coding and labeling synchronous, saving processes.

◆ Barcode printer + computer + software system is available to print barcode and other information to the label online and label online.

◆ Optional ink inkjet printer or laser inkjet printer, to achieve the production date on the product and other functions, inkjet labeling synchronous, saving processes.

◆ Automatic feeding device can be customized according to the product to realize automatic feeding.