Description

Descriptions:

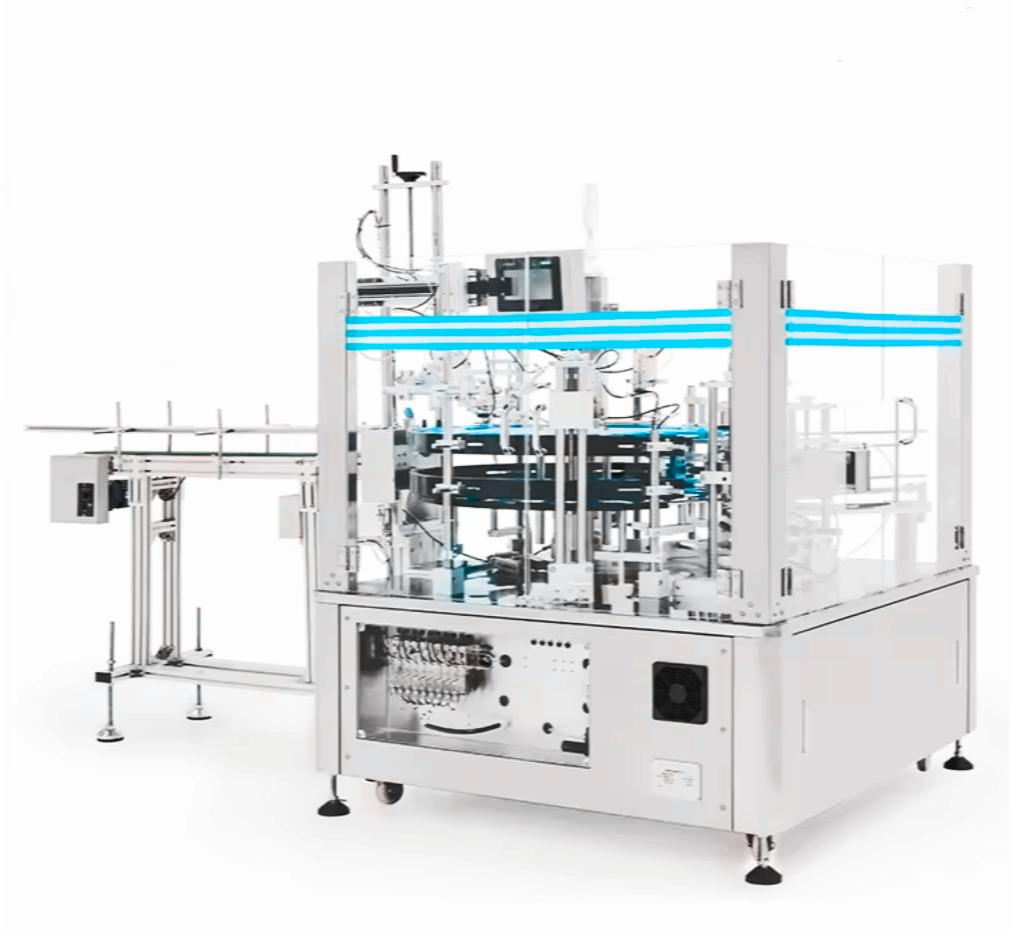

ZONGKI wrap around case packer has been designed with high quality and well known for their reputation of reliability and durability. Machine type ranging from low speed wrap around case packer to high speed wrap around case packer can meet different customers’ requirements and productivity level.

ZONGKI has years of experience in manufacturing wrap around case packer. The high quality of all material and strict technical standard for all mechanical and electric components, with high efficiency, precise assembling and rigorous testing procedures, lead to high performance ,safe and durable products.

Drop type wrap around case packer ZK-WR-30D is designed for packaging regular beverage.

Machine features:

- Drop type wrap around case packer is suitable for packaging regular beverage

- Easy to adjust for different bottles with variable bottle height and diameter, package form and carton size

- Full servo motor control main engine, PLC control system and Siemens mark machine operation reliable

- The machine is equipped with safety guard

- The mechanical part is made of stainless steel, chrome plating steel and other strong corrosion resistance aluminum alloy, which greatly improves the quality of anti-rust

- The machine will sound alarm if there is no carton sheet

- High efficiency and energy saving

- Easy maintenance

Basic information:

Power supply: 3P 380V+10%/50HZ, 12.5Kw

Air pressure: 0.4Mpa~0.6Mpa

Control voltage: 24V DC

Bottle size: Provided by user

lCase size: Provided by user

lHot glue system: Nordson

Speed: Max.:20 cartons /min

Worktable height: Standard 1150mm (Can be customized)

Dimensions: L7500 x W2600 x2100mm

(Depends on the design)

l Machine weight: 5~6 tons (Depends on the design)

Noise: ≤75DB

Environment: Humidity ≤ 98%, Temperature 20-40oC

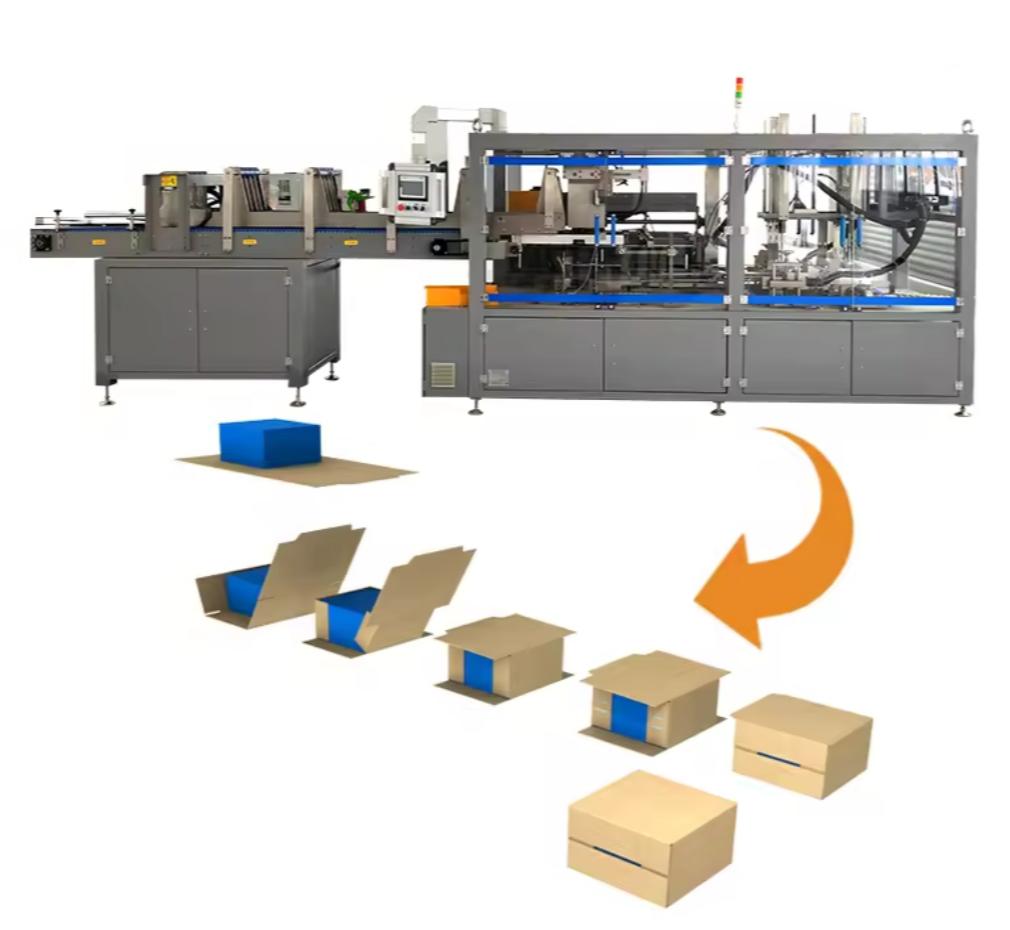

Working process:

Start the machine->Paper sheet is sucked by sucker from the temporary storage to the lower working station->meanwhile, the products is conveyed to the paper sheet->The paper sheet is formed as a carton for products->Hot glue sealing the carton->Output the packed products