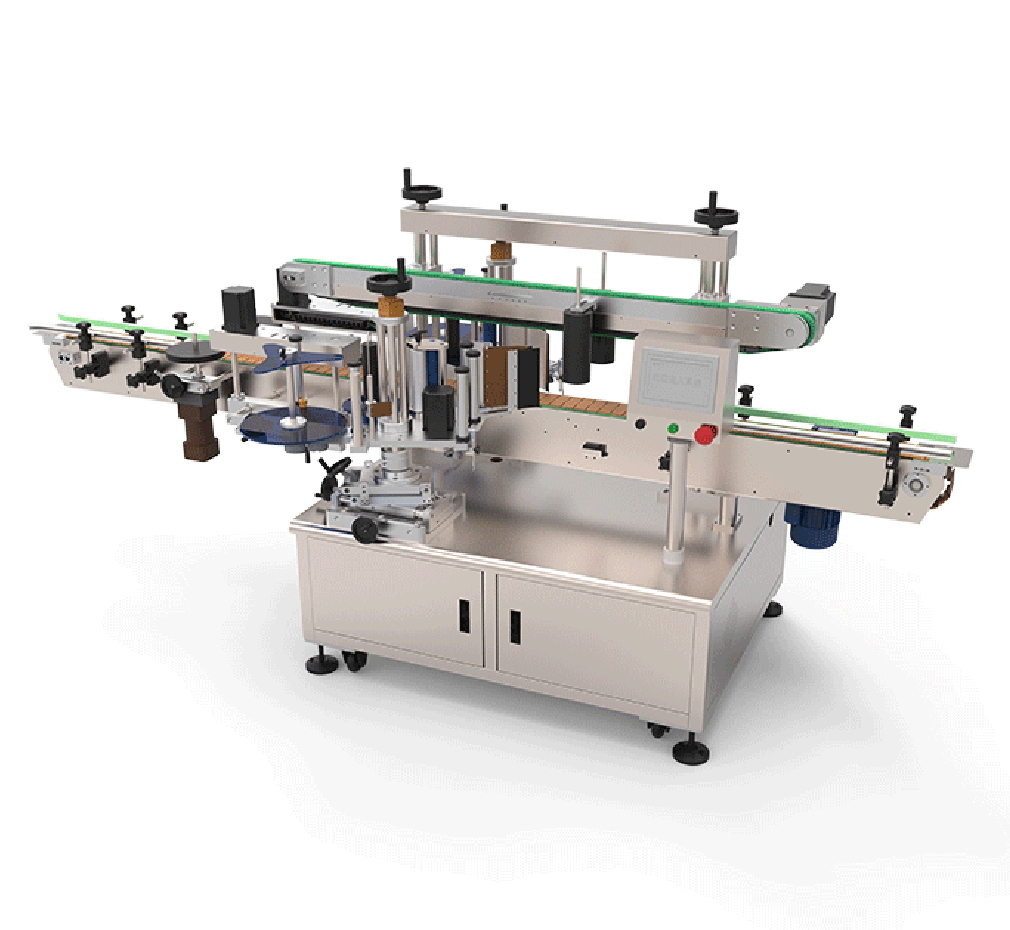

Description

High precision semi-automatic plane labeling machine

Model: ZK-T101

| Labeling accuracy | ±0.5mm (excluding product and label errors) |

| Labeling speed | 15 ~ 25 pieces/min (depending on product size) |

| Applicable product diameter (for round bottles) and height | Length (front and back) : 20mm ~ 200mm |

| Width (left and right direction) : 20mm ~ 180mm | |

| Height: 0.2mm ~ 65mm | |

| Applicable label size | Length: 10mm ~ 40mm |

| Width (base paper width) : 5mm ~ 50mm | |

| Overall size | Approx. 550mm×420mm×780mm (length × width × height) |

| Applicable power supply | 220V/50HZ |

| Machine weight | About 67Kg |

Basic function

◆ The machine adopts the working mode of suction, and the label is attached to the product during the downward movement of the suction head.

◆ High precision marking structure (4 cylinders), absorb the label and then strip the label, stable marking, especially used in a variety of small label labeling, labeling accuracy is high. 0.2mm;

◆ The labeling position of some products is concave, and the suction head with the same shape as the concave can be designed according to the need, and it is extended into the concave surface for labeling.

◆ It is used to paste self-adhesive labels on various flat and small curved surfaces. Such as battery end face, lipstick bottom, electronic chips, USB connectors, chargers, electronic products and other stickers, bar codes, mobile phone shell two-dimensional code, double-sided tape and other labels; Design desktop structure, small footprint.

Optional function:

◆ Automatic induction switch is optional to realize automatic downlabeling after induction;

◆ Optional safety grating, safety protection;

◆ Optional fine tuning fixture platform, convenient replacement of different products to adjust the labeling position;

◆ The rotating disk feeding device can be customized to achieve continuous feeding at multiple stations and improve the speed;