Description

INTRODUCTION

Siemens PLC Control, High speed 50 cartons/min

The high-speed carton erector is a new machine designed by our company for large-scale warehousing, logistics and other industries. Cam drive system and the connecting rod are used to control the entire machine motion instead of manual operation. Sucking cartons, forming, folding and sealing the bottom can be completed at one time, and the producing speed can reach 50 ctns/min. The machine structure design adopts a 45° oblique angle without ash drop design and automatic warning reminder function of broken tape or no tape, which is more convenient for maintenance. The installation of transparent protective doors is convenient and fast for changing the tape. This carton erector is also widely used in food, medicine, beverage, tobacco, daily chemical, electronics and other industries.

CHARACTERISTICS

Easy maintenance. The machine structure design adopts a 45° oblique angle without dust, which is easy to maintain;

Durable spare-parts Use famous brand spare-parts like Siemens, Schneider to ensure accurate erector molding control, which is stable and durable.

High speed. The machine adopts a cam drive system combined with a connecting rod to control the entire machine motion, and the producing speed reaches 50 ctns/min.

Simple operation. Adopt PLC+ man-machine interface control, easy operation, simple maintenance and stable performance;

Flexible expansion: Can be used with automatic packaging lines.

PARAMETERS

| Model Parameters | |

| Carton Opening Speed | 50 ctns/min |

| Carton Size | L250-450 ×W150-400 × H150-350mm |

| Power Supply | 220V 50Hz 1 Phase |

| Power | 1000W |

| Adhesive Tape Width | 48/60mm 2 inch ,2.5 inch |

| Carton Storage Quantity | 80pcs (800mm) |

| Air Consumption | 450NL/min |

| Air Compressing | 6kg/cm³ |

| Table Height | 960~1000mm |

| Machine dimension | L3120xW1410xH1900mm |

| Machine Weight | 1200Kg |

MACHINE DETAILS

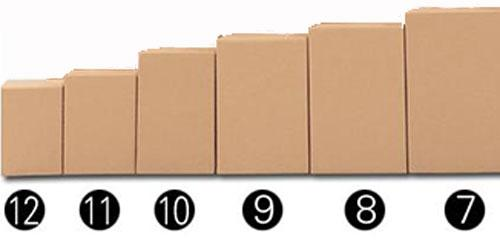

Available for multiple size of cartons

Minimum size is 250mm.

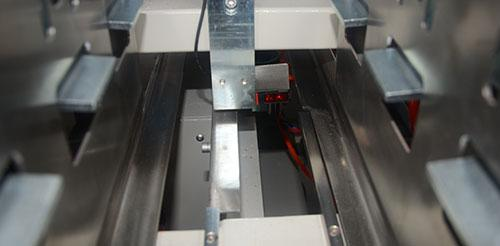

Double gear

The double-gear mechanism design is adopted. Compared with the traditional pin-in method, the carton has a larger bearing capacity and is more stable when taking out the carton. The carton stock can reach 600mm

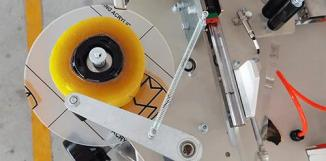

Automatic alarm warning for broken tape

No tape or broken tape will sound an alarm, which is convenient for users to replace and adjust in time, saving time.

Innovative rail design

The unpacking design is upgraded from the sliding shaft to the guide rail with light sliding, and low noise, which makes the machine more stable and in long service life.

High performance motor

The stable, powerful and durable motor is selected, which can work quickly and efficiently without interruption, with strong stability.

Man-machine interface

The Siemens PLC control program is selected, and the operation interface is simple, which is convenient for the operator to input data and adjust.

Alarm prompt function

With tape and carton out of material alarm function, no material is automatically reminded, which is convenient for operators to add materials in time.

Carton forming mechanism

Because of light and thin carton, the carton forming mechanism adopts suction cup and imitated manipulator design, which is convenient to use less force to improve the efficiency of rapid

carton forming in the process.

CONFIGURATION

| Name | Brand |

| Low Voltage Appliances | Schneider |

| PLC | Siemens |

| Touchscreen | Siemens |

| Pneumatic Components | AirTAC |

| Photoelectric | Leuze |

| Mechanical valve | SMC |

| Cylinder | AirTAC |

| Vacuum components | SMC、 Meta Design |

Reminder: Because the product of our company are constantly updated, please refer to the contract and reserved without prior notice, please understand! It can also be matched according to customer needs, welcome to consult customer service staff.