Description

Descriptions:

Zongki has years of experience in manufacturing shrink wrapping machines. The high quality of all material and strict technical standard for all mechanical and electric components, with high efficiency, precise assembling and rigorous testing procedures, lead to high performance, safe and durable products.

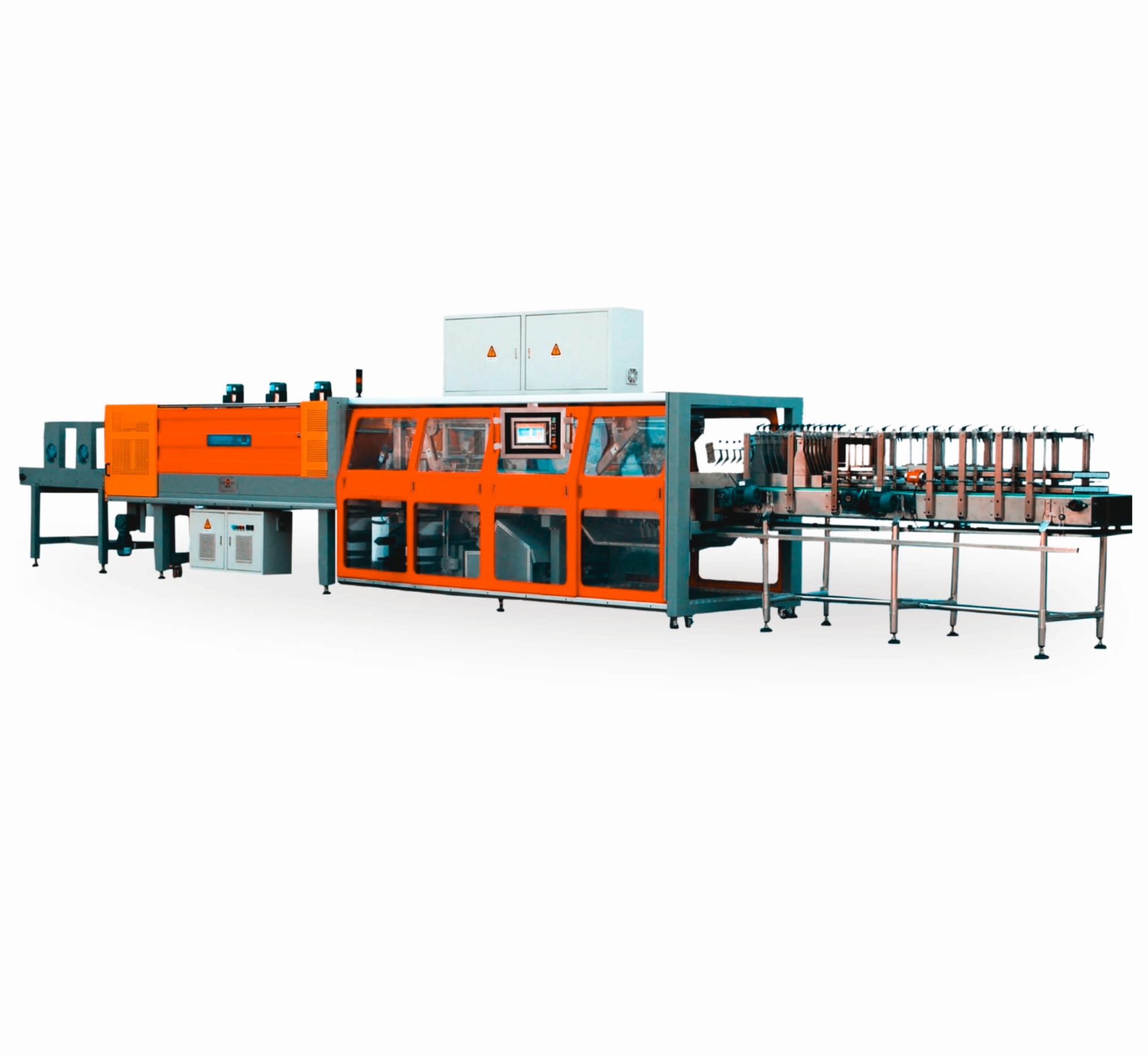

ZKB-40T single lane shrink wrapping machine is designed for shrink packaging various kinds of regular bottles and cans.

Machine features:

- CE certification

- 6servo motors controls main part, which makes the machine in a quality of high efficiency and stability

- Wind power can be adjustable

- The height of cooling fan can be adjustable so as to fit differentsize of bottles

- Long service life

- Can be connected with production line

- Energy saving

- Easy maintenance

Basic information:

Power supply: AC380V 50Hz 11.28Kw tunnel 63.75Kw

Machine size: L8349*W1670*H2508mm

Tunnel size: L4595*W1570*H2348mm

Working table height: 1150~1250mm ±50mm (Can be customized)

Packing speed: Max 30 pcs/minute

Air consumption: 60L

Air pressure: 4~6Kgf/cm2

Suitable packing material: Bottles (PET/Glass/HDPE)

Cans (Aluminum/steel)

Pots (PET/glass/HDPE)

Object combination: 2×2, 2×3, 3×4, and 4×6

Bottle dimension: 0.25L~2L round or square

Film: Transparent film or pre-painted film

Pneumatic components: Germany Festo or SMC

Motor: Germany SEW

PLC: Germany Siemens

Photoelectricity: Germany P+F

Converter: French Schneider

Working process:

Connect the machine with production line->Start the machine->Products can be conveyed by the belt and then separated into one combination->Separated combinations enter to shrink tunnel in a sequence->Finish shrink wrapping-> Transfer the finished products to the next station or take away the products

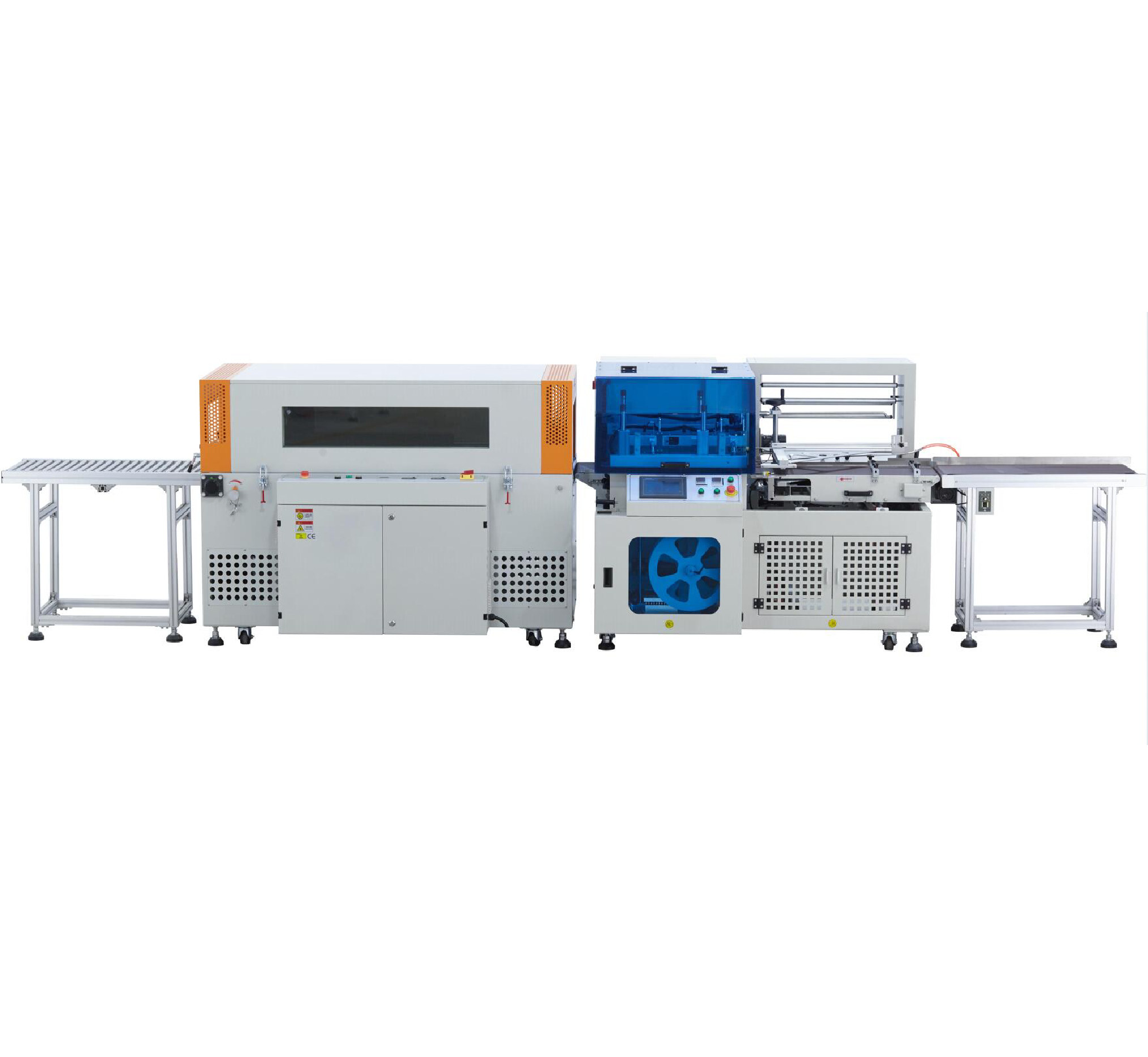

Shrink tunnel

- Power supply voltage: 380V, 50Hz,

- Total heating power: 75KW

- Machine size: L*W*H: 4550mm×980mm×2200mm (height can be customized according to product size)

- Furnace chamber size: L*W*H:3000mm×450mm×525mm (height can be customized according to product size)

- Furnace chamber import network with size: 750 mm

- Table height: 1150±50mm (customizable)

- Conveying speed: 0-18m/min adjust the speed according to the supporting film machine

- Conveyor belt: 12A crankshaft mesh chain

- Machine color: light grey

- Heating body: 1500W/ piece, 48 pieces

- Temperature control range: 0-400℃ adjustable

- Range of use: 150-230℃

- Machine weight: 1130kg

- Heating mode: heating is mainly based on hot air circulation, supplemented by direct heat. There are temperature sensors around the conveying direction to control the temperature

- The heating tube is installed vertically, which can be maintained with installation and reduce energy consumption.

- Film parameters: LDPE (low density polyethylene)

- Film type: transparent and white LDPE film (or color film)

- Maximum width of film roll: 740 mm

- Film thickness: 06~0.09 mm

- Density: 92 g/cm3

- Maximum outer diameter of film coil: 400 mm

- Film contraction ratio: longitudinal 70±5 %, transverse 20±5 %

- Film core coil diameter: 75 mm

- Thermal shrinkage temperature: 180-210℃

- The control cabinet is connected with a moisturizing layer to isolate the heat source. The bottom of the heat shrink machine is equipped with a protective plate to reduce heat loss