Description

Descriptions:

This machine ZK-PF-6000 Washing-Filing-Capping machine is used for fill mineral,pure water and other non-carbonated beverage.

The quality of all materials used and the high technical standards for all mechanical and electronic components combined with highly efficient and precise assembling and testing procedures lead to high performance, safe and durable products.

Machine features:

- Advanced gravity filling technology

- Magnetic torque is applied on bottle screw-capping

- Humanized interface touch-screen and PLC control system

- All parts connected with water are made of food grade stainless steel.

- Simple structure, easy operation, Low noise, reliable running, accurate filling.

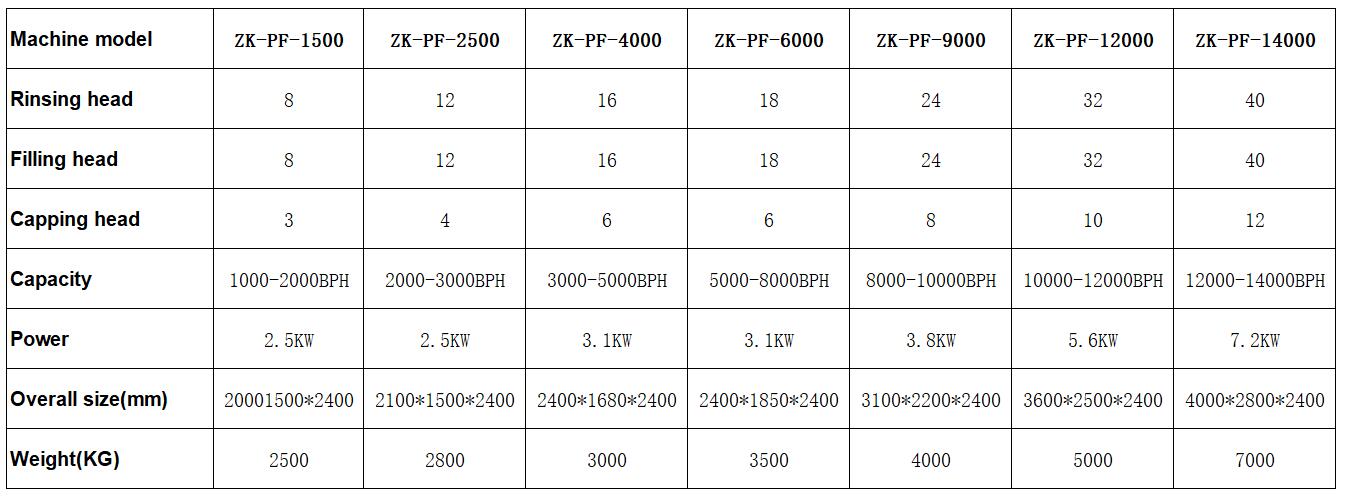

Basic information

Capacity 6000 BPH

Washing heads 18

Washing time 2-2.5 s

Filling valve heads 18

Filling valve flow speed 140-160ml/s

Capping heads 8

Apply to bottle: D=50-100mm, H=150-320mm

Capping moment 0.6-2.8Nm

Power 3.1KW

Compress air consumption 0.25 Nm3/min (0.6Mpa hour)

Water consumption Rinsing bottle need 2.5m3/h (0.2-0.25Mpa)

Overall dimension 2400*1850*2400 mm

Weight 3500 kg

Working process

1.Water Filling Mono block

-PET bottles enter the machine by distributing bottle star wheel, and making the bottle mouth down with clamp pincers and overturning device by grip the bottles mouth. After sanitary water rinse and drain, automatically turn to the bottle up, bottle after a star wheel conveyor to the filling machine. Mainly parts of equipment structure, washing media material, external protect frame are high-quality stainless steel, open-gear transmission.

-Into-water pipes has pressure meter. Washing machine has water defrosting tray for recycling washing water.

- Filler

-This part is mainly used for filling water after finishing bottle rinse.

-Filling machine is introduced by Germany technology, use normal pressure fill principle to design and produce.

-It adopt normal pressure mechanism valve, make filling with high speed and high precision of liquid level. Double leading bars elevator structure to make the bottle up and stability.

-The main drive transmission adopts gear transmission that is opening combination drive, with high efficiency, low noise, long life, easy maintenance, full lubrication, use of transducer control the main drive motor speed, this machine is non degree conversion frequency speed control.

-Bottle guiding system, the structure is simple, it can quick and easy change according to different bottle volume, this whole machine transported by clipping bottle neck method.

-PLC controlled by itself, fault display online, e.g. bottle block or non-cap etc.

-In filling tank the product material control itself, the liquid level height adopt liquid level sensor to test, make sure stability liquid level and reliable filling.

-This machine main spare parts and electricity component is import product.

- Capper

-This part is mainly use the cap that ordering in cap elevator and capping on the finished fill bottle, and then deliver to the followed procedure.

-Capping machine through reducer drive back to the wheel rotation, make the cap under the action of the centrifugal force away from the hopper. It has up or down cap separating device at the exit, when the wrong side cap passes, it will automatically fall into the return pipe and blown into the hopper by wind power. Only right cap can be successfully come into the slide, the cap amount in hopper automatic detection by optical switch to control the cap transmission machine, to ensure the best results under the cap.

-When the right cap into slide path, it will immediately enter cap feeder to prevent accidents. At the same time it has an prevent anti -cap dial to ensure that the cap plate into the feed cap is correct. In slide has also a pair of photoelectric switch, when detected no cap, it will immediately stop the machine operation.