POF film (Polyolefin Shrink Film) and PE film (Polyethylene Film) are both types of plastic films used in various packaging applications, but they have some key differences:

-

Material Composition:

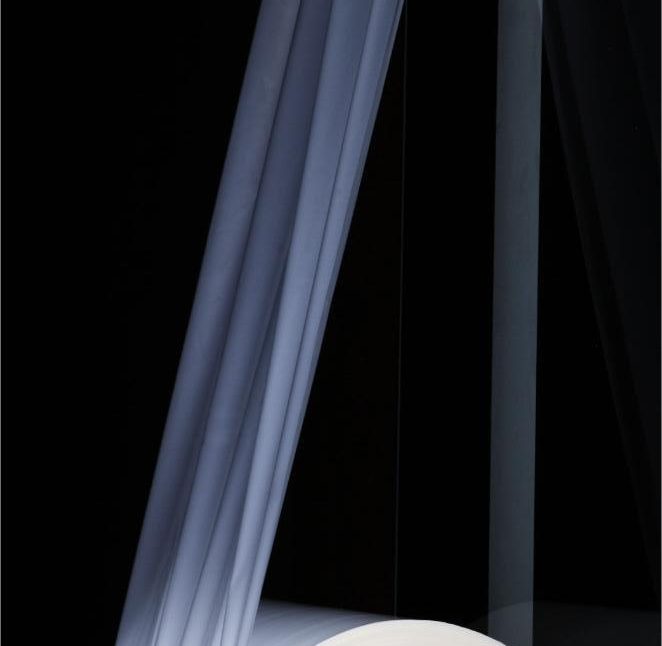

- POF Film: Made from polyolefin resins, primarily polypropylene (PP) and polyethylene (PE) copolymers. These films are designed to shrink when heat is applied.

- PE Film: Made from pure polyethylene resin. PE films are not shrinkable by heat.

-

Shrinkability:

- POF Film: Has excellent shrinkability, allowing it to tightly wrap around products and provide a secure seal. This is achieved through the controlled application of heat.

- PE Film: Does not shrink when heat is applied. It remains in its original shape and size.

-

Clarity and Transparency:

- POF Film: Typically has excellent clarity and transparency, making it suitable for packaging products that need to be displayed clearly.

- PE Film: Also has good clarity, but may not match the transparency of high-end POF films.

-

Sealing Properties:

- Both POF and PE films can be sealed using heat or adhesives, but the sealing properties may vary depending on the specific film formulation and thickness.

-

Cost:

- POF Film: Generally costs more than PE film due to its specialized material composition and shrinkability.

- PE Film: Represents a more economical choice for packaging applications that do not require shrinkability.

-

Environmental Impact:

- Both POF and PE films are made from petroleum-based plastics, so they have similar environmental impacts. However, some POF films may be formulated to be more recyclable or biodegradable.

-

Applications:

- POF Film: Commonly used for shrink wrapping pallets, cartons, bundles, and individual products. It is ideal for packaging applications that require a tight, secure seal.

- PE Film: Used for a wide range of packaging applications, including bags, liners, and wraps. It is suitable for applications that do not require shrinkability.

In summary, the key difference between POF film and PE film lies in their shrinkability. POF film is designed to shrink when heat is applied, while PE film remains in its original shape and size. Other differences include material composition, clarity, sealing properties, cost, and potential environmental impact.